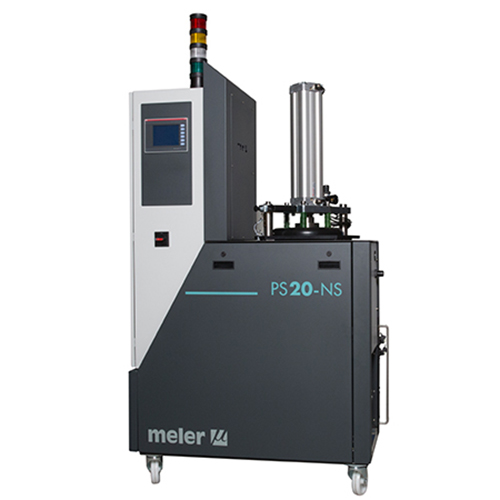

Meler PS200

Melter used to melt adhesive in 200 litre cans directly from the packaging. Production can be interrupted during a number of days, without the need to supply inert gas. Simple placement of adhesive drum.

This unit has a wide manual and automatic flow rate adjustment range. The flow rate is adjusted by means of regulating the speed of the 10-80 rpm pump motor.

The electrical and hydraulic connections are located on the top of the melter plate, which makes connecting hoses an easy task. Up to four hoses-applicators can be connected to the outputs of these units.The bypass valve of the pumps of the unit is a vital safety element, since it limits the maximum pressure in the system.

An air injection system is used to eject the melter plate; this system counteracts the effects of the vacuum generated inside the canister. Optionally, this process can be carried out automatically.

MAIN APPLICATIONS

Automotive industry, bookbinding, graphic arts (transparent cases), pre-melter for rollers and other types of tanks, coating of plank edges, post-forming, sealing counter-tops and coating mouldings.