Megaflex Polyurethane Belts

Megaflex timing belts are manufactured in thermoplastic polyurethane, with continuous spiral steel cords. this type of belt, developed by our research & development, offers good running characteristics and high traction loads. They are especially suited for power transmission and conveying with high loads and high speeds (up to 10.000 rpm). The addition of a nylon coating on the teeth during production enhances the running properties for specific applications and reduces the noise frictional coefficient. An extra thickness of special coating is also possible on the back of the belt offering extra protection against aggressive or heavy products. Megaflex belts are truly endless, enabling them to deliver exceptional performance. Megadyne Megaflex timing belts are available from 1.500 up to 22.700 mm length.

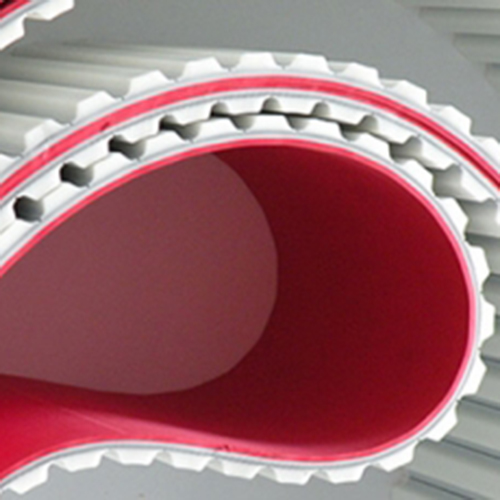

MEGAFLEX MAIN COMPONENTS

The body of the belts is white thermoplastic polyurethane 92 ShA, characterised by high levels of wear resistance even in the presence of shock and surge loading.

High strength helicoidal zinked steel tension members allow high breaking load and extremely low elongation.

The combination of these high grade materials improves belt performances which can be summarized as follows:

exceptional resistance to abrasion and tooth shear

low coefficient of friction

high flexibility

ozone and temperature resistance ( -25 °C / +80 °C)

oil, grease and gasoline resistance

MECHANICAL AND CHEMICAL CHARACTERISTICS

Constant dimensions

Noiseless

Free maintenance

High flexibility

High resistance steel traction cords, with little stretching and top flexibility

Linear speeds up to 20 m/s

Low pretension

Constant length

High abrasion resistance

Ageing, Hydrolysis, Ozone resistant

Working temperature -25 °C / +80 °C High resistance to Oils, Greases and Gasoline Fairly Acid-proof and Alkali-proof

MEGAFLEX APPLICATIONS

Thanks to their features, MEGAFLEX belts can be successfully used in a wide range of applications such as:

High Power Transmission

Ceramic Industry

Marble & Stone Industry

Glass Industry

Heavy Transport systems

Wood Industry

Food Industry